Steam Heating VS Electric Heating for Brewhouse Heating Systems

Electric heating and steam heating are two types of heating that are often used in the brewing process. If you are confused by the choice between electricity heating system and a steam heating system we’ll show you the differences.

Electric Heating

Advantage: The electricity heating is more used in a commercial environment and have a low heating lost.

Disadvantage: Technical limitations. Since most of the commercial brewing equipment requires step-by-step saccharification, the saccharification process needs to be heated, which requires higher heating methods and design requirements. Therefore, it’s tot suit for high concentration wort mashing. It will scorch even if the agitation and circulation both operating.

Steam Heating

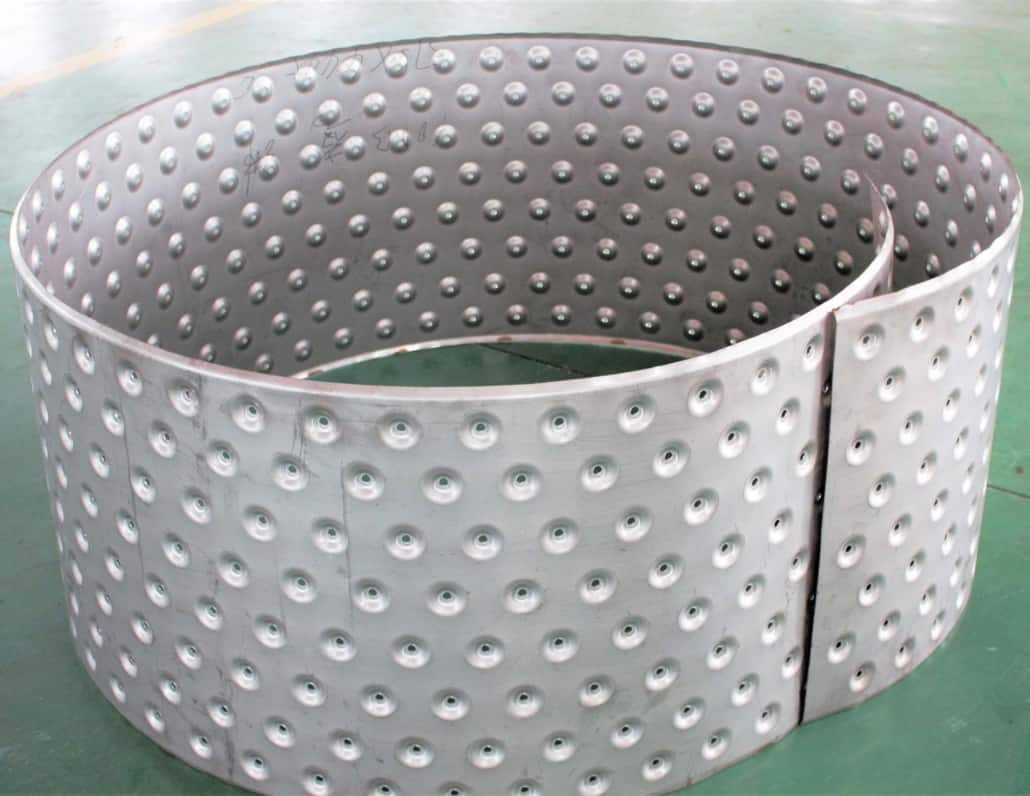

Advantage: The steam heating is a reasonable choice. The temperature raise smoothly and uniformly, and suit for different technical demands. Steam heating is evenly heated, and there is no paste pot phenomenon.

Disadvantage: Heavy heat lost (in comparison), and power consumption is higher- Steam heating uses 15 percent more power compared with electric heating.

Energy saving

Both electric & steam heating can be used for energy saving in other processes.

Electric heating- Reusing the hot water after the exchange with wort.

Steam heating- Recycling the condensed water.

Equipment maintenance

Advantage: Electric heating system is easy to maintain.

But the steam generator will need a regular clean and check ups, such as:

- Cleaning the heating tube and generator inner wall without scaling every quarter

- Checking the content of salt for demineralized water salt tank

- Washing the boiler by acid, avoiding the blocking of the pressure controller and safety valve by scaling

- Manually testing of the safety valve every week

- Test the safety valve every six months for any failures

We can help you to choose the best brewing equipment based on your needs. View our nano brewing equipment page.

Frequently Asked Questions (FAQ)

- Q1: Which brewhouse heating system is better for step-mashing and decoction?

A1: Steam heating. Steam jackets provide uniform, controllable heat across vessel surfaces, minimizing scorching and enabling precise step ramps and decoction rests. - Q2: When does electric heating make the most sense?

A2: For small to mid-scale brewhouses (≤10–15 hL), direct electric elements in kettles/HLTs are cost-effective, easy to install, and low-maintenance—especially where natural gas/steam permitting is difficult. - Q3: How do I reduce scorching risk with electric elements?

A3: Use low-watt-density elements, maintain vigorous but appropriate recirculation, keep elements submerged, implement power ramping via PID control, and avoid very high gravity mashes in element-heated mash tuns. - Q4: What utility and infrastructure differences should I plan for?

A4: Steam requires a boiler or steam generator, condensate return, blowdown handling, and regular inspections. Electric needs sufficient three-phase power, upgraded panels, and proper wiring/overcurrent protection. - Q5: Which option is greener?

A5: It depends on your local energy mix and heat recovery. Electric tied to renewables can be lowest carbon. Steam paired with stack heat recovery and condensate return can be competitive. Model your site-specific CO2e.

2025 Industry Trends: Brewhouse Heating Systems

- Electrification with renewables: Breweries leverage solar/wind PPAs and time-of-use tariffs to lower electric heating costs and carbon intensity.

- High-efficiency steam: Compact once-through steam generators with O2 trim, VFD feedwater pumps, and stack economizers cut fuel use.

- Advanced controls: Model predictive control (MPC) for step-mash ramps and boil vigor reduces overshoot and energy by 10–20%.

- Integrated heat recovery: Wider adoption of vapor condensers to preheat HLT, and deeper condensate return optimization.

- Compliance and safety: Stricter boiler codes and cybersecurity expectations for burner management and PLCs.

2025 Performance Benchmarks and Cost Signals

| Metric | Electric Heating | Steam Heating | Notes / Sources |

|---|---|---|---|

| Typical scale sweet spot | ≤10–15 hL | ≥10 hL to 50+ hL | Steam excels as batch size/throughput rises |

| Ramp control for step-mash | Good (elements + PID) | Excellent (uniform jackets) | Less risk of hotspots with steam |

| Scorching risk (mash/kettle) | Medium (mitigable) | Low | Depends on watt density and agitation |

| Installation complexity | Low–Medium | Medium–High | Boilers require permits, venting, inspections |

| Maintenance burden | Low | Medium–High | Boiler treatment, inspections, safety devices |

| Energy intensity (kWh/hL eq.) | 6–10 | 5–9 | With heat recovery and optimized boils |

| Capex (relative) | $ | $$–$$$ | Steam higher upfront; scales better |

| Carbon intensity sensitivity | High to grid mix | High to fuel type | Electrify + renewables vs. high-efficiency gas |

| Best-in-class water use impact | Neutral | Positive with condensate return | BA Sustainability Benchmarks |

| 2025 adoption signals | Growing with RE power | Strong in mid/large plants | BA, MBAA case studies |

Selected sources:

- Brewers Association Sustainability Benchmarking and Calculators: https://www.brewersassociation.org

- Master Brewers Association of the Americas (MBAA) Technical Quarterly: https://www.mbaa.com

- U.S. DOE Better Plants (steam systems): https://www.energy.gov

- ASBC Methods (process QA context): https://www.asbcnet.org

Latest Research Cases

Case Study 1: Steam Retrofit with Heat Recovery Cuts Utilities (2025)

Background: A 20 hL brewery running an older firetube boiler faced rising gas costs and long step-mash ramps.

Solution: Replaced with a high-efficiency once-through steam generator, added stack economizer and vapor condenser to preheat the HLT; implemented MPC for mash steps and boil vigor via PLC/HMI.

Results: Brewhouse energy intensity dropped 19%; time-to-rest reduced by 28%; water intensity improved from 4.6 to 3.4 hL/hL; payback estimated at 2.4 years. Shared at an MBAA district seminar (2025).

Case Study 2: Electrification Leveraging Renewable Tariffs (2024)

Background: A 7 hL brewpub with limited space and no gas line needed precise control and low maintenance.

Solution: Installed low-watt-density electric elements in kettle and HLT, upgraded 3-phase service, added TOU-based scheduling and solar PPA; tuned PID for step ramps and boil control.

Results: Scope 2 CO2e fell ~55% vs. prior mixed-fuel setup; energy costs down 12% under TOU optimization; zero scorching incidents across 140 brews; maintenance hours cut by ~30% year-over-year.

Expert Opinions

- Dr. Johannes Tippmann, Professor of Brewing Engineering, TUM Weihenstephan

Viewpoint: “Uniform heat flux from steam jackets remains the gold standard for complex mash programs and larger vessels, especially when paired with advanced controls.” Source: Academic lectures/publications on brewhouse design. - Mary Pellettieri, Brewing Quality Consultant; Author

Viewpoint: “Whatever the heating choice, validated ramp rates, sensor calibration, and CIP verification determine flavor consistency and foam stability.” Source: Industry workshops and Quality Management for Breweries. - Kai Troester (Kai Tro), Brewing process author and engineer

Viewpoint: “For small systems, electric elements with proper watt density and circulation deliver clean wort and tight temperature control without boiler overhead.” Source: Technical articles and brewing forums.

Practical Tools/Resources

- Brewers Association: Energy and water calculators, sustainability guides — https://www.brewersassociation.org

- DOE Steam System Optimization (steam traps, economizers, O2 trim) — https://www.energy.gov

- ASBC Methods: thermal/process measurements for QA — https://www.asbcnet.org

- DSIRE (USA): Incentives for electrification, high-efficiency boilers, heat recovery — https://www.dsireusa.org

- OPC Foundation (OPC UA): integrating heating controls with brewhouse automation — https://opcfoundation.org

- Boiler and Pressure Vessel Codes (jurisdictional): consult state/provincial authority or NBIC — https://www.nationalboard.org

Last updated: 2025-09-01

Changelog: Added 5 FAQs, 2025 trends with benchmark table and sources, two recent case studies (steam retrofit with heat recovery; small-scale electrification with renewables), expert viewpoints, and practical resources tailored to brewhouse heating systems

Next review date & triggers: 2026-03-01 or earlier if BA updates energy benchmarks, DOE releases new steam/electrification guidance, or utility tariff/incentive programs change

Share this entry

Interested in learning more about Brewing Systems including additional details and pricing information? Please use the form below to contact us!

YOLONG BREWERY EQUIPMENT FAQS

- Commercial Brewery / Craft Brewery / Microbrewery / Nanobrewery

- What is The Difference Between Craft Beer and Industrial Beer?

- The Bespoke Differences In Custom Brewing Systems

- Everything You Need to Know About Kettle Souring

- How to Choose Brewing Equipment for Your business?

- How To Choose The-Best Partner To Build Your Commercial Microbrewing System?

- Two Detection Sensors That You Need To Use In Your Brewhouse System

- Remote Control Applications in Brewing Equipment/How does it work?

- How To Clean Your Brand New Brewery Tanks?