Steam Heating VS Electric Heating for Brewhouse Heating Systems

Electric heating and steam heating are two types of heating that are often used in the brewing process. If you are confused by the choice between electricity heating system and a steam heating system we’ll show you the differences.

Electric Heating

Advantage: The electricity heating is more used in a commercial environment and have a low heating lost.

Disadvantage: Technical limitations. Since most of the commercial brewing equipment requires step-by-step saccharification, the saccharification process needs to be heated, which requires higher heating methods and design requirements. Therefore it’s tot suit for high concentration wort mashing. It will scorch even if the agitation and circulation both operating.

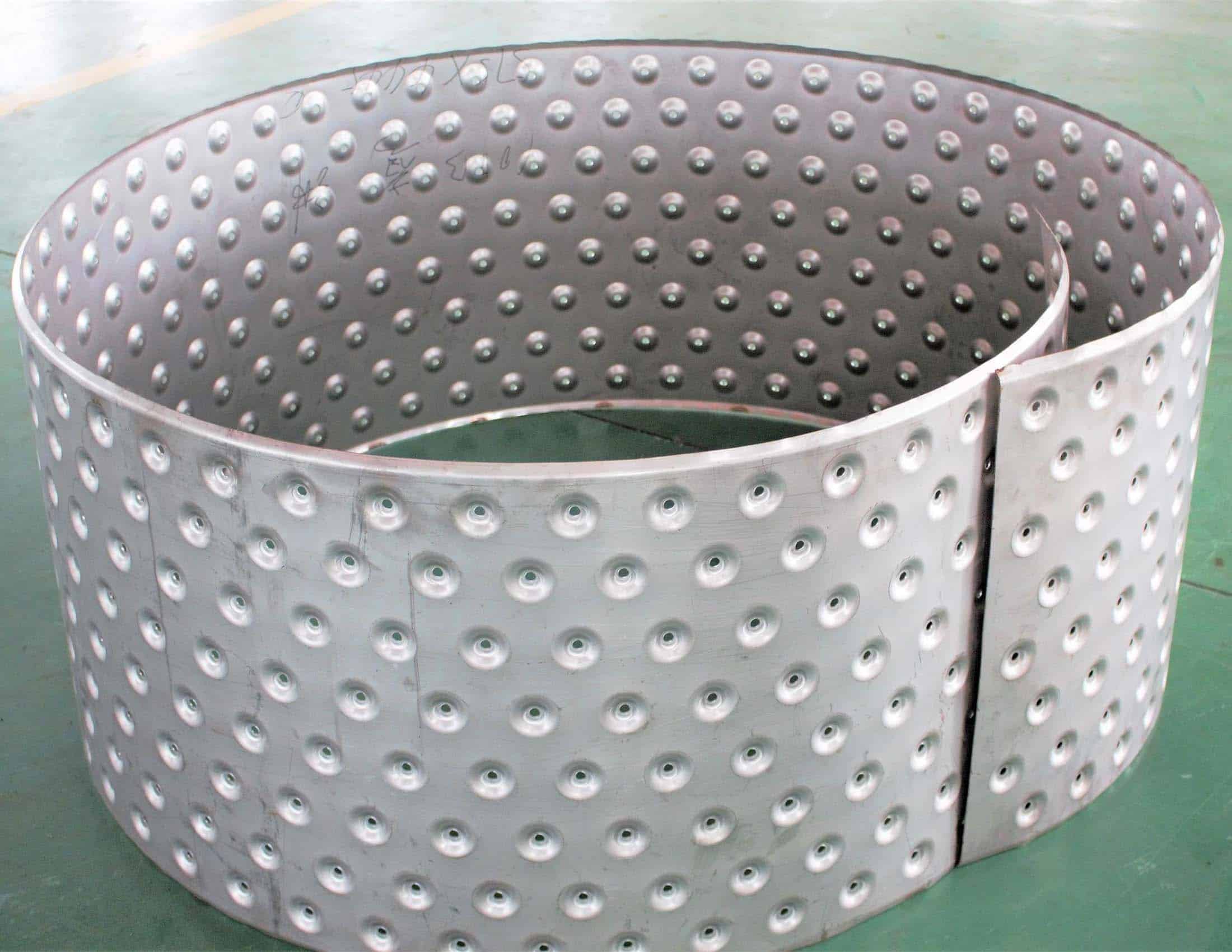

Steam Heating

Advantage: The steam heating is a reasonable choice. The temperature raise smoothly and uniformly, and suit for different technical demands. Steam heating is evenly heated, and there is no paste pot phenomenon.

Disadvantage: Heavy heat lost (in comparison), and power consumption is higher- Steam heating uses 15 percent more power compared with electric heating.

Energy saving

Both electric & steam heating can be used for energy saving in other processes.

Electric heating- Reusing the hot water after the exchange with wort.

Steam heating- Recycling the condensed water.

Equipment maintenance

Advantage: Electric heating system is easy to maintain.

But the steam generator will need a regular clean and check ups, such as:

- Cleaning the heating tube and generator inner wall without scaling every quarter

- Checking the content of salt for demineralized water salt tank

- Washing the boiler by acid, avoiding the blocking of the pressure controller and safety valve by scaling

- Manually testing of the safety valve every week

- Test the safety valve every six months for any failures

We can help you to choose the best brewing equipment based on your needs. View our nano brewing equipment page.

CONTACT US