Brewery Vessels

Product categories

- Spares & Accessories (0)

- MALT TECHNOLOGY (1)

- BREWING SYSTEM (6)

- BREWERY TANK (8)

- HOP TECHNOLOGY (2)

- YEAST TECHNOLOGY (2)

- SS TANK (5)

- CONTROL SYSTEM (2)

- PACKAGE MACHINE (1)

- PROCESS SYSTEMS (1)

Brewery Vessels

Brewery vessels are specialized containers used throughout the beer brewing process. These vessels are designed to accommodate various stages of beer production, including mashing, boiling, fermenting, and conditioning. Investing in high-quality equipment is crucial for any brewery’s success.

Types of Brewery Vessels

There are several types of brewery vessels used in the brewing process, each serving a specific purpose. Here, we will explore some of the most common brewery vessels found in breweries of all sizes.

Mash Tuns

Mash tuns are the vessels where the mashing process takes place. Mashing involves mixing crushed grains, usually malted barley, with hot water to create a mash. This process allows enzymes to break down the grains’ starches into fermentable sugars. Mash tuns are typically insulated to maintain a consistent temperature throughout the mashing process.

Lauter Tuns

Lauter tuns are used to separate the liquid wort from the solid grain material after mashing. This vessel contains a false bottom or a series of screens that allow the wort to drain while leaving the spent grain behind. The wort is then transferred to the boil kettle for the next stage of the brewing process.

Boil Kettles

Boil kettles, also known as brew kettles or copper kettles, are where the wort is boiled and hops are added. This stage of the brewing process serves to sanitize the wort, extract hop flavors and aromas, and concentrate the wort by evaporating excess water. Boil kettles are typically made of stainless steel or copper and are designed to handle high temperatures and large volumes of liquid.

Fermentation Vessels

Fermentation vessels, also known as fermenters or uni-tanks, are where the wort ferments and transforms into beer. Yeast is added to the wort, and the fermentation process begins, converting sugars into alcohol and carbon dioxide. Fermentation vessels come in various shapes and sizes, from small carboys for homebrewing to large, conical stainless-steel tanks for commercial breweries.

Brite Tanks

Brite tanks, also known as bright beer tanks or serving tanks, are used to store beer after fermentation and conditioning have been completed. These vessels are designed to clarify and carbonate the beer before it is packaged or served. Brite tanks are typically made of stainless steel and may be equipped with cooling jackets to maintain a consistent temperature.

These are just a few examples of the different types of brewery vessels that play essential roles in the brewing process. Selecting the right vessels for your brewery will depend on your specific needs, budget, and the scale of your operation.

How Much Do Brewery Vessels Cost?

The cost of brewery vessels varies greatly depending on several factors, such as size, materials, manufacturer, and the specific type of vessel. Here is a rough estimate of the costs associated with different brewery vessels:

1. Mash Tuns: For small-scale homebrewing, a mash tun can cost between $100 to $500. In contrast, commercial-grade mash tuns can range from a few thousand dollars to tens of thousands, depending on the size and features.

2. Lauter Tuns: Similar to mash tuns, lauter tuns for homebrewers are relatively inexpensive, typically priced between $100 to $500. For larger commercial breweries, lauter tuns can cost several thousand dollars or more.

3. Boil Kettles: Boil kettles for homebrewing can range from $100 to $1,000, depending on the material, size, and additional features like built-in heating elements. Commercial boil kettles can cost anywhere from a few thousand dollars to well over $50,000, depending on the size and configuration.

4.Fermentation Vessels: Homebrewers can find fermentation vessels such as carboys and buckets for as low as $20 to $200. Commercial-grade fermentation vessels, like stainless steel conical fermenters, can start at a few thousand dollars and go up to hundreds of thousands of dollars for very large capacities.

5. Brite Tanks: For homebrewers, small brite tanks or kegs can cost between $100 to $500. In commercial breweries, brite tanks can range from a few thousand dollars to tens of thousands or more, depending on the size and features.

It’s essential to consider your specific needs and budget when selecting brewery vessels. Keep in mind that investing in high-quality equipment can save money in the long run by reducing the risk of equipment failure and ensuring a consistent, high-quality product.

Proper Care and Maintenance of Brewery Vessels

Proper care and maintenance of brewery vessels are crucial for ensuring the longevity and performance of your equipment, as well as the quality and consistency of your beer. Below are some essential tips for maintaining your brewery vessels:

Regular Cleaning

Cleanliness is paramount in the brewing process. Each vessel should be thoroughly cleaned after each use to remove any residual beer, yeast, or other contaminants. Use brewery-approved cleaning agents and follow the manufacturer’s guidelines for cleaning procedures. Be sure to rinse all cleaning agents thoroughly to avoid any potential off-flavors in your beer.

Periodic Inspections

Perform regular visual inspections of your brewery vessels, checking for any signs of wear, corrosion, or damage. Pay special attention to seals, gaskets, valves, and other components that may wear out over time. Replace any damaged or worn parts as needed to prevent leaks or equipment failure.

Preventative Maintenance

In addition to cleaning and inspections, it’s essential to perform preventative maintenance on your brewery vessels. This may include tasks such as lubricating valves, tightening fittings, and calibrating temperature and pressure sensors. Follow the manufacturer’s recommendations for preventative maintenance schedules and procedures.

Proper Storage

When not in use, store your brewery vessels in a clean, dry environment to prevent any potential contamination or damage. For long-term storage, it’s a good idea to cover vessels with a breathable cover or tarp to keep out dust and debris.

Maintain Records

Keep detailed records of all cleaning, inspections, and maintenance performed on your brewery vessels. This will help you track the condition of your equipment and identify any potential issues before they become critical. Additionally, maintaining thorough records can be helpful for troubleshooting and warranty claims.

By following these guidelines, you can ensure that your brewery vessels remain in optimal condition and provide consistent, high-quality results for your brewing endeavors.

Manufacturers of Brewery Vessels

There are numerous manufacturers of brewery vessels in the market, catering to the needs of both small-scale and large-scale breweries. Some of the top manufacturers in the industry include:

Yolong Brewtech

Yolong Brewtech is a manufacturer that focuses on producing high-quality, customizable brewery vessels for breweries of all sizes. They offer a variety of products, including fermentation vessels, brite tanks, mash tuns, and boil kettles. Yolong is known for its excellent customer support, quality craftsmanship, and flexibility in meeting the specific needs of their clients.Learn more about their products and services on their website: https://yolongbrewtech.com/

Ss Brewtech

Ss Brewtech is a popular manufacturer of brewery vessels and equipment, offering a wide range of products for homebrewers and commercial breweries. Their product lineup includes fermenters, mash tuns, brew kettles, and more, all made from high-quality stainless steel.

Blichmann Engineering

Blichmann Engineering is well-known for their innovative and high-quality brewing equipment, including brewery vessels such as boil kettles, fermenters, and mash tuns. They cater to both homebrewers and professional brewers, focusing on user-friendly designs and exceptional performance.

Premier Stainless Systems

Premier Stainless Systems specializes in producing high-quality, custom stainless steel brewery vessels and equipment for commercial breweries. Their offerings include fermenters, brite tanks, mash tuns, and more. They are known for their attention to detail and exceptional craftsmanship.

GW Kent

GW Kent is a leading supplier of brewery vessels and equipment for the craft brewing industry. They offer a wide range of products, including fermentation tanks, brite tanks, and brew kettles. GW Kent is committed to providing reliable, high-quality equipment to breweries of all sizes.

When choosing a manufacturer for your brewery vessels, it’s important to consider factors such as the company’s reputation, product quality, and customer support. Seek recommendations from fellow brewers, read reviews, and conduct research to ensure you’re making the right choice for your brewery.

Why choose Yolong Brewery Vessels?

Yolong is a reputable manufacturer that focuses on providing high-quality and customizable brewing equipment. There are several reasons to consider Yolong Brewery Vessels for your brewing needs:

Quality and Craftsmanship

Yolong Brewery Vessels are known for their high-quality craftsmanship and attention to detail. They use top-grade materials, such as stainless steel, to ensure the durability and longevity of their products. Yolong’s brewery vessels are designed to withstand the rigors of the brewing process while maintaining optimal performance.

Customization and Flexibility

One of the main reasons to choose Yolong Brewery Vessels is their ability to customize and adapt their products to your specific needs. Whether you require a unique design, additional features, or a specific size, Yolong will work with you to create the perfect brewery vessel solution for your operation. This level of customization and flexibility allows you to build a brewery that suits your exact requirements and preferences.

Stellar Customer Support

Yolong takes pride in providing exceptional customer support to their clients. They are always available to answer questions, address concerns, and provide guidance on proper care and maintenance for their products. This dedication to customer satisfaction ensures that you will have a reliable partner in your brewing journey.

Competitive Pricing

While maintaining high standards in quality and craftsmanship, Yolong Brewery Vessels also offers competitive pricing on their products. This makes them an excellent choice for breweries looking for a balance between cost and quality.

International Experience

Yolong has experience working with breweries from various countries, giving them a unique understanding of the diverse needs and requirements of different markets. This international experience allows them to cater to a wide range of clients and provide tailored solutions for breweries worldwide.

In summary, choosing Yolong Brewery Vessels means investing in high-quality, customizable equipment backed by exceptional customer support. Their commitment to meeting the specific needs of each brewery makes them an excellent choice for brewers looking to invest in reliable and efficient brewing equipment.

Recent Update

Is a 3.5 BBL Brewhouse Right for You?

Starting your own craft brewery? Upgrading your garage hobby into a serious operation? Or maybe you’re eyeing a space in a local pub where your

Can Beginners Use a 3 BBL Fermenter

The Core Functions of the 3 bbl Fermenter A 3 bbl fermenter is one of those unsung heroes in the world of brewing. You might

20 BBL Brewhouse for Sale – High-Quality Systems Ready to Ship

20 BBL Brewhouse Introduction Ever dreamt of owning a nano brewery that cranks out delicious craft beer at scale without breaking the bank? Welcome to

About Yolong

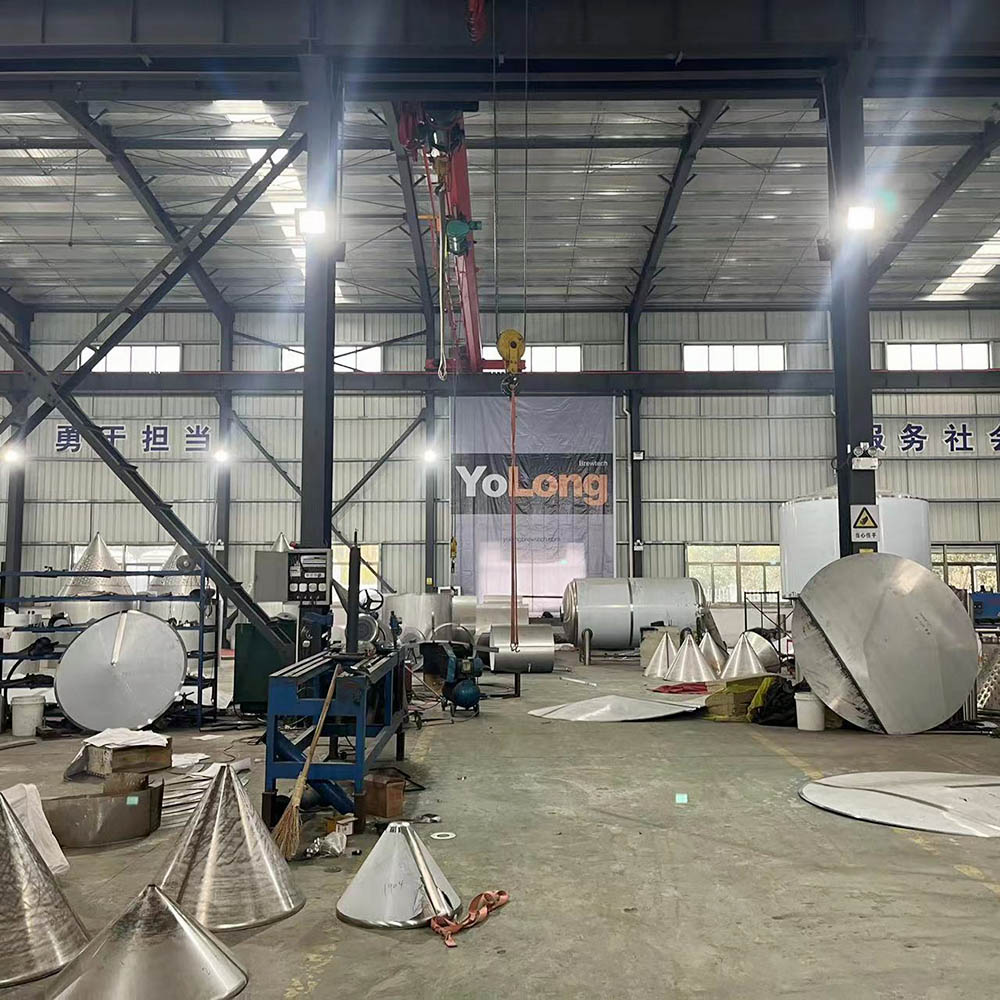

Founded in 2004 – With over 15 years’ experience in the brewery equipment manufacturing business – YoLong Brewtech has set the standard for fabricating custom-designed and pre-made brewing equipment at the highest levels of value and quality. Our dedicated and experienced team has helped us become an industry leader in manufacturing products for one of the most fast-growing industry sectors in the world: Beverages; Beer; Cold Brewed Coffee; Kombucha; Infused Teas; Wine.

YoLong Brewtech’s staff work together in our state-of-the-art 36,000 m2 / 3350 ft2 manufacturing plant in the Ningbo City Economic Development Zone, China. We ensure every custom-designed project is fabricated to our customer’s exact specifications. The YoLong manufacturing plant is able to meet virtually any specification a customer requires.

Our Factory Gallery

Why Choose Us

Yolong come to the table not only as a craft beer equipment solution provider, but also a partner. We’re always combining our business acumen and entrepreneurial vision with amazing craft beer equipment manufacturing expertise and the ability to execute quickly and efficiently, taking your idea to market under fast-response.

- Lean Production Line

- Full Range Of Product

- Maximum Quality

- Minimizing Worry

- Comprehensive Solutions

- Professional Team

- Years Of Experience

- Trusted Brand

“We focus our capabilities on providing one-stop services. You will find us very eager to know about your need, so to offer you the best solution. “

Alan – Founder

We Own Factory

We have our own factory since established, which means there is no trader between us, which means that we can achieve the most satisfactory level in terms of price, MOQ and product services.

Reasonable Price

We are a factory, not a trading company, and the relationship between you and me is direct, which saves both money and hassle. The direct production process reduces costs, so we can give you very competitive prices.

Unmatched

Service.

Unmatched

excellent.

One-Stop

Most factory products cannot meet the demand of product diversity, but we have a multitude of craft beer equipment products to choose from. We offer a truly one-stop service. Yolong have years of knowledge in this industry, and are willing to guide you along your way.

Common Vision

Good Service

Most factories primarily focus only on manufacturing, which leads to a lacking of sales and service awareness. Yolong have our own sales team, technicians and after-sales staff, which means that not only can we provide faster and better-quality service.