PACKAGE MACHINE

Product categories

- PROCESS SYSTEMS (1)

- Spares & Accessories (0)

- MALT TECHNOLOGY (1)

- BREWING SYSTEM (6)

- BREWERY TANK (8)

- HOP TECHNOLOGY (2)

- YEAST TECHNOLOGY (2)

- SS TANK (5)

- CONTROL SYSTEM (2)

- PACKAGE MACHINE (1)

Package machine

Package machines are an essential part of the manufacturing industry, used to package various products in different types of containers. There are several types of package machines available in the market, each designed to cater to specific packaging needs. In this article, we will discuss the various types of package machines, how to choose the right one for your business, their cost, and some popular manufacturers.

Package machine types

Package machines play a critical role in the manufacturing industry, providing an efficient way to package products for distribution and sale. There are various types of package machines available in the market, each designed to cater to specific packaging needs.

- Filling Machines: Filling machines are used to fill containers with liquid or powder products. They come in different types, such as piston fillers, gravity fillers, and volumetric fillers. Piston fillers are suitable for filling thick or viscous liquids, while gravity fillers are ideal for thin or low-viscosity liquids. Volumetric fillers are used to fill precise amounts of liquid or powder into containers, ensuring accurate measurements and minimal waste. Filling machines are widely used in the food and beverage, pharmaceutical, and cosmetic industries.

- Sealing Machines: Sealing machines are used to seal products in their containers to prevent contamination and spoilage. They come in different types, such as induction sealers, vacuum sealers, and heat sealers. Induction sealers use electromagnetic induction to heat and seal the container’s lid, while vacuum sealers remove air from the container before sealing. Heat sealers use heat to melt and seal the container’s plastic or foil lid. Sealing machines are widely used in the food, pharmaceutical, and chemical industries.

- Labeling Machines: Labeling machines are used to label packages with essential information, such as product name, expiry date, and barcodes. They come in different types, such as wrap-around labelers, front-and-back labelers, and top labelers. Wrap-around labelers apply a label that wraps around the container, while front-and-back labelers apply labels to the front and back of the container. Top labelers apply labels to the top of the container. Labeling machines are widely used in the food and beverage, pharmaceutical, and cosmetic industries.

In conclusion, package machines are essential for efficient packaging and distribution of products. Filling machines, sealing machines, and labeling machines are among the most widely used types of package machines. Each type of machine is designed to cater to specific packaging needs, providing accuracy, consistency, and efficiency. When selecting a package machine, it is essential to evaluate the packaging needs carefully and choose a machine that meets those needs effectively.

How to choose package machine?

Choosing the right package machine is crucial for ensuring efficient and effective packaging of products. There are various factors to consider when selecting a package machine, including the type of product, packaging material, production capacity, and budget.

- Choosing the right package machine is crucial for ensuring efficient and effective packaging of products. There are various factors to consider when selecting a package machine, including the type of product, packaging material, production capacity, and budget.Type of Product: The type of product being packaged is an essential factor to consider when selecting a package machine. Different products require different packaging methods and machines. For instance, liquids require filling machines, while solids require sealing machines.

Packaging Material: The packaging material is another critical factor to consider when choosing a package machine. Different packaging materials, such as plastic, glass, or metal, require different machines to package them effectively.

Production Capacity: Production capacity is a crucial factor when selecting a package machine. The machine’s speed and efficiency must match the production capacity to ensure that it can keep up with demand and avoid downtime.

Budget: Budget is an essential consideration when choosing a package machine. Package machines can vary significantly in cost, so it is essential to choose a machine that fits within the budget without compromising quality and efficiency.

How Much Do Package Machines Cost?

The cost of a package machine can vary significantly, depending on its type, size, and features. The cost of a basic filling machine can range from a few thousand dollars to tens of thousands of dollars. A sealing machine can cost anywhere from a few thousand dollars to over a hundred thousand dollars, depending on its size and features. Labeling machines are the most expensive, with costs ranging from tens of thousands of dollars to several hundred thousand dollars.

It is essential to keep in mind that the initial cost of a package machine is not the only cost to consider. There are also costs associated with installation, maintenance, and repairs. It is crucial to factor these costs into the overall budget when considering a package machine.

package machine manufacturers

Selecting a reliable and reputable manufacturer is crucial when purchasing a package machine. There are various manufacturers of package machines in the market, and it can be challenging to choose the right one. In this article, we will discuss some of the popular manufacturers of package machines.

Yolong Brewtech: Yolong Brewtech is a manufacturer of package machines that specializes in brewing equipment, such as beer brewing systems, filling machines, and capping machines. They provide high-quality machines that are designed to meet the needs of the brewing industry.Learn more about their products and services on their website: https://yolongbrewtech.com/

Bosch Packaging Technology: Bosch Packaging Technology is a leading manufacturer of package machines that provides packaging solutions for various industries, such as food, pharmaceuticals, and chemicals. They offer a wide range of machines, including filling machines, sealing machines, and labeling machines.

Krones AG: Krones AG is a German manufacturer of package machines that provides packaging solutions for the beverage industry, such as beer, soft drinks, and water. They offer a comprehensive range of machines, including filling machines, labeling machines, and packaging machines.

Tetra Pak: Tetra Pak is a Swedish manufacturer of package machines that specializes in packaging solutions for the food and beverage industry. They offer a range of machines, including filling machines, sealing machines, and packaging machines.

Sidel Group: Sidel Group is a French manufacturer of package machines that provides packaging solutions for the beverage, food, and home care industries. They offer a comprehensive range of machines, including filling machines, labeling machines, and packaging machines.

ProMach: ProMach is a US-based manufacturer of package machines that provides packaging solutions for various industries, such as food, pharmaceuticals, and consumer goods. They offer a wide range of machines, including filling machines, sealing machines, and labeling machines.

In conclusion, there are various manufacturers of package machines in the market. Yolong Brewtech, Bosch Packaging Technology, Krones AG, Tetra Pak, Sidel Group, and ProMach are among the popular manufacturers. When selecting a manufacturer, it is essential to consider their reputation, quality of machines, price, and after-sales support. Careful consideration of these factors will help you select a reliable and reputable manufacturer that provides high-quality package machines that meet your packaging needs effectively.

Why choose Yolong package machine?

When selecting a package machine, it is essential to choose a reliable and reputable manufacturer that provides high-quality machines. Yolong Brewtech is one such manufacturer that specializes in brewing equipment, such as beer brewing systems, filling machines, and capping machines. In this article, we will discuss why you should choose Yolong package machines for your packaging needs.

Reasons to Choose Yolong Package Machines

Quality: Yolong package machines are designed and built with high-quality materials and advanced technology, ensuring optimal performance and minimal downtime. Their machines undergo rigorous quality control testing before delivery to ensure they meet the highest standards.

Customization: Yolong package machines are highly customizable, allowing you to tailor the machines to your specific packaging needs. They can customize machines based on your product type, packaging material, production capacity, and budget.

Innovation: Yolong Brewtech is committed to innovation and continuous improvement, ensuring that their machines are up-to-date with the latest technology and trends in the industry. They regularly introduce new features and enhancements to their machines to meet the changing needs of the industry.

After-sales Support: Yolong Brewtech provides excellent after-sales support, including maintenance, repairs, and spare parts. They have a team of experienced technicians who are available to provide technical support and assistance to ensure optimal machine performance.

Competitive Pricing: Yolong package machines are competitively priced, providing high-quality machines at a reasonable price. They offer a range of machines to suit various budgets, ensuring that you can find a machine that fits within your budget without compromising quality.

In conclusion, Yolong package machines are an excellent choice for those looking for high-quality, customizable, and innovative package machines. Yolong Brewtech’s commitment to quality, customization, innovation, after-sales support, and competitive pricing make them a reliable and reputable manufacturer in the industry. When considering a package machine, Yolong Brewtech is a manufacturer that should be at the top of your list.

Recent Update

Is a 3.5 BBL Brewhouse Right for You?

Starting your own craft brewery? Upgrading your garage hobby into a serious operation? Or maybe you’re eyeing a space in a local pub where your

Can Beginners Use a 3 BBL Fermenter

The Core Functions of the 3 bbl Fermenter A 3 bbl fermenter is one of those unsung heroes in the world of brewing. You might

20 BBL Brewhouse for Sale – High-Quality Systems Ready to Ship

20 BBL Brewhouse Introduction Ever dreamt of owning a nano brewery that cranks out delicious craft beer at scale without breaking the bank? Welcome to

About Yolong

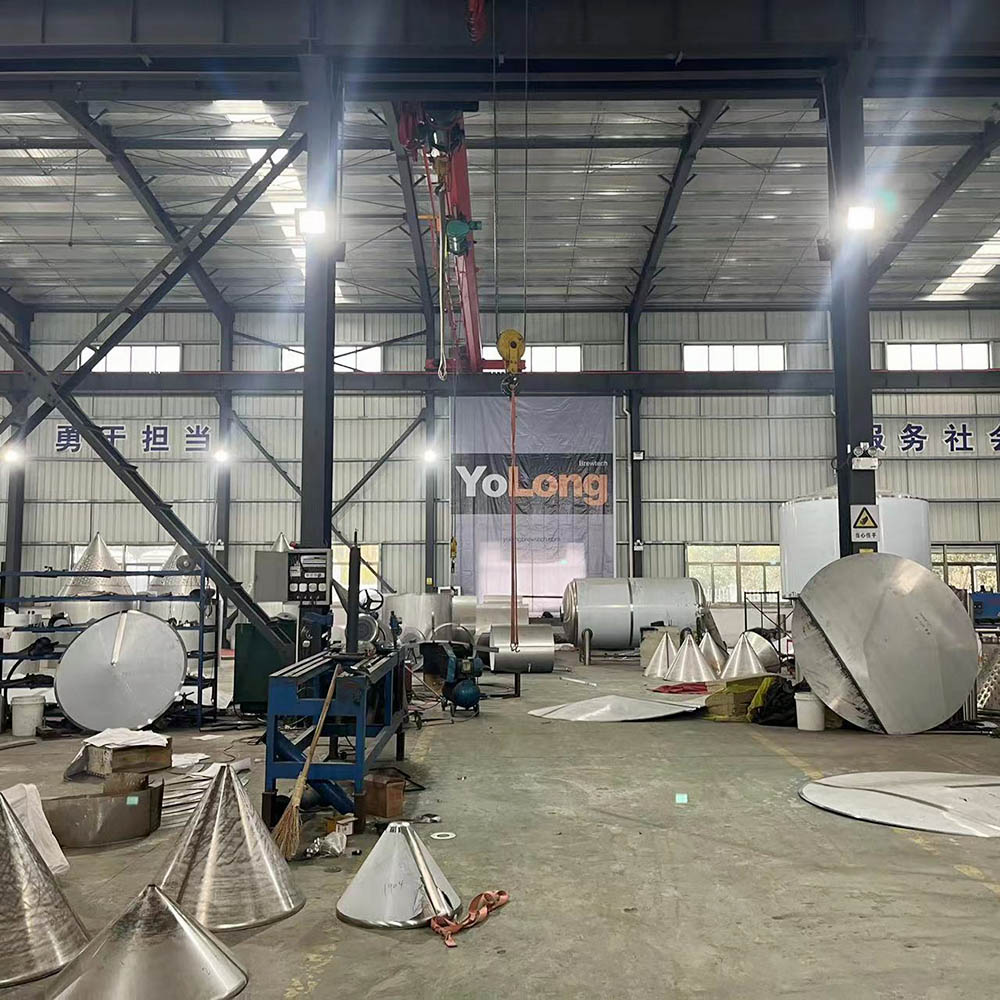

Founded in 2004 – With over 15 years’ experience in the brewery equipment manufacturing business – YoLong Brewtech has set the standard for fabricating custom-designed and pre-made brewing equipment at the highest levels of value and quality. Our dedicated and experienced team has helped us become an industry leader in manufacturing products for one of the most fast-growing industry sectors in the world: Beverages; Beer; Cold Brewed Coffee; Kombucha; Infused Teas; Wine.

YoLong Brewtech’s staff work together in our state-of-the-art 36,000 m2 / 3350 ft2 manufacturing plant in the Ningbo City Economic Development Zone, China. We ensure every custom-designed project is fabricated to our customer’s exact specifications. The YoLong manufacturing plant is able to meet virtually any specification a customer requires.

Our Factory Gallery

Why Choose Us

Yolong come to the table not only as a craft beer equipment solution provider, but also a partner. We’re always combining our business acumen and entrepreneurial vision with amazing craft beer equipment manufacturing expertise and the ability to execute quickly and efficiently, taking your idea to market under fast-response.

- Lean Production Line

- Full Range Of Product

- Maximum Quality

- Minimizing Worry

- Comprehensive Solutions

- Professional Team

- Years Of Experience

- Trusted Brand

“We focus our capabilities on providing one-stop services. You will find us very eager to know about your need, so to offer you the best solution. “

Alan – Founder

Unmatched

Service.

Unmatched

excellent.

We Own Factory

We have our own factory since established, which means there is no trader between us, which means that we can achieve the most satisfactory level in terms of price, MOQ and product services.

Reasonable Price

We are a factory, not a trading company, and the relationship between you and me is direct, which saves both money and hassle. The direct production process reduces costs, so we can give you very competitive prices.

Unmatched

Service.

Unmatched

excellent.

One-Stop

Most factory products cannot meet the demand of product diversity, but we have a multitude of craft beer equipment products to choose from. We offer a truly one-stop service. Yolong have years of knowledge in this industry, and are willing to guide you along your way.

Common Vision

Good Service

Most factories primarily focus only on manufacturing, which leads to a lacking of sales and service awareness. Yolong have our own sales team, technicians and after-sales staff, which means that not only can we provide faster and better-quality service.