When it comes to choosing a brewery tank, several factors come into play. Here are some essential considerations that can help you make an informed decision.

Tank Size

One of the critical factors to consider when choosing a brewery tank is its size. The tank size should be appropriate for the amount of beer you plan to brew and the available space in your brewery. You don’t want to invest in a tank that’s too small or too big for your needs.

The tank size can also impact the brewing process, as it can affect the temperature and pressure inside the tank. Therefore, it’s essential to choose a tank size that can accommodate your brewing volume and meet your specific requirements.

Tank Material

Brewery tanks are typically made of stainless steel, which is a popular material in the brewing industry due to its durability, ease of cleaning, and resistance to corrosion. However, not all stainless steel is the same, and it’s essential to consider the type and grade of stainless steel used in the tank’s construction.

The thickness of the tank walls and the finish can also affect the tank’s performance and longevity. Therefore, it’s crucial to choose a tank made of high-quality stainless steel with the appropriate thickness and finish for your brewing needs.

Tank Features

The design features of the brewery tank can affect its performance and functionality. Some essential features to consider include insulation, cooling and heating systems, pressure gauges, manways, and control systems.

Insulation can help maintain the temperature inside the tank, while cooling and heating systems can regulate the temperature according to the brewing process. Pressure gauges can help monitor the pressure inside the tank, while manways provide access for cleaning and maintenance. Control systems can automate the brewing process and improve efficiency.

Consider the features that are essential for your brewing process and choose a tank that meets your specific requirements.

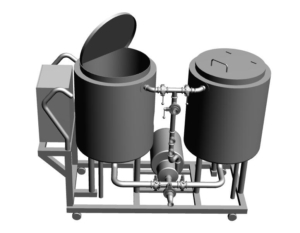

Tank Type

There are different types of brewery tanks, each with a specific function in the brewing process. Some common types include fermenters, bright tanks, and storage tanks. The tank type you choose will depend on your brewing process and the number of tanks you need for your brewing operation.

Fermenters are used to ferment the beer and can come in different sizes and shapes. Bright tanks are used for conditioning and carbonating the beer, while storage tanks are used for storing the beer before packaging. Choose a tank type that suits your brewing needs and can help you achieve your desired beer quality and taste.

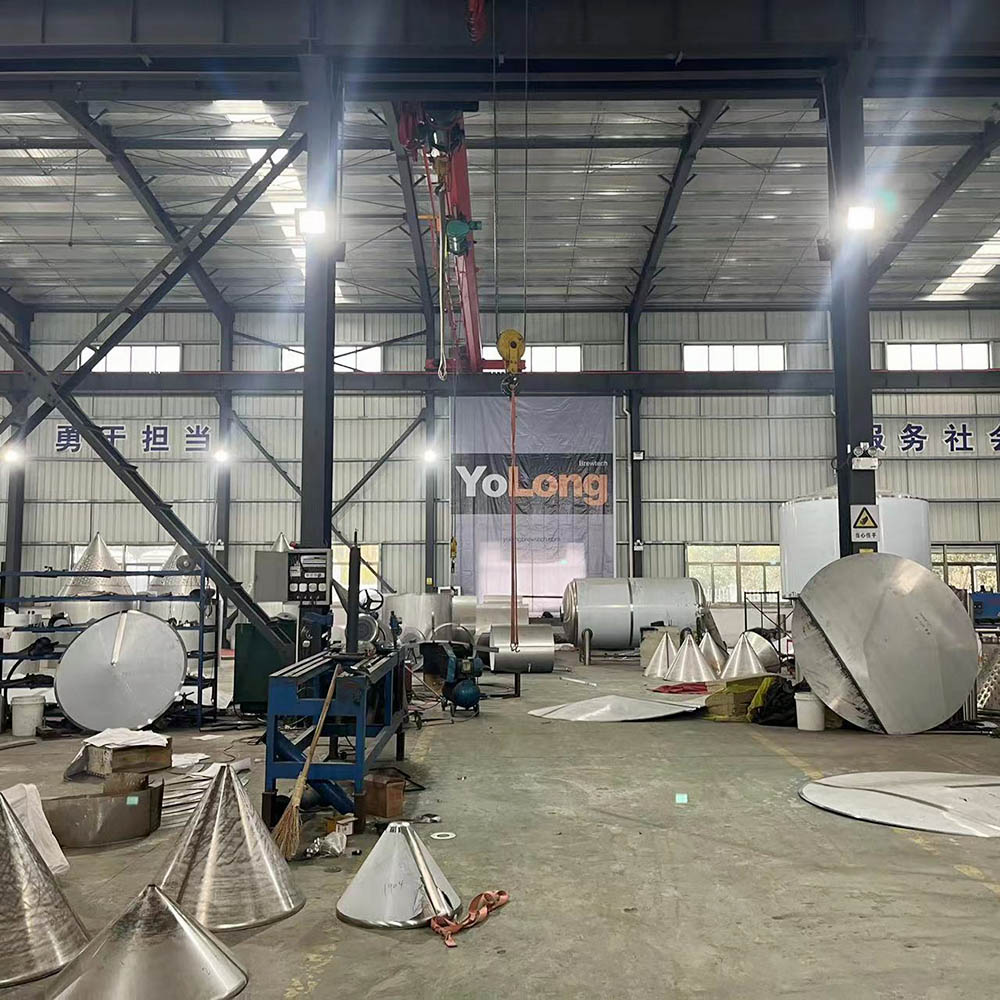

Manufacturer Reputation

The manufacturer’s reputation is an essential factor to consider when choosing a brewery tank. You want to choose a reputable manufacturer with a proven track record of producing high-quality tanks that meet industry standards and certifications.

Do your research and read reviews from other brewers to determine the manufacturer’s reputation and reliability. You can also ask for recommendations from other brewers in the industry.

Cost

The cost of the brewery tank is an essential consideration, especially if you’re on a budget. However, it’s essential to choose a tank that offers the best value for your money without compromising on quality.

Consider the long-term benefits and costs of the tank, such as its durability, performance, and maintenance requirements. Choose a tank that fits your budget and can help you achieve your brewing goals without sacrificing quality.

In conclusion, choosing the right brewery tank can significantly impact the quality and taste of your beer. Consider the tank size, material, features, type, manufacturer reputation, and cost when making your decision. With the right tank, you can brew high-quality beer that meets your specific brewing needs and requirements.