Unitank / Beer Fermentation Tank

A specialist brewtech unitank is an essential piece of equipment in any craft beer brewery. A unitank fermenter is no ordinary beer tank: think of a uni tank as beer tanks where the magic happens! Tank beer tastes amazing, and it’s easy to see why steel tank brewing has really taken off since its conception.

A unitank fermenter is a dual-purpose combination brewery tank used as both a fermentation tank and a brite beer tank, which can carbonate beer with CO2 while inside the unitank fermenter. YoLong unitanks allow the brewer to carbonate beer quickly (under 24 hours) by using a carb stone. During this process, it is possible to monitor the head pressure to a very precise degree inside the brewing tanks.

Each meticulously crafted and welded YoLong unitank includes cooling jackets, insulation, and a cone bottom. All welding is done under a protection-gas atmosphere, with inside and outside grinding and smoothing, as well as seamlessly welded cooling jackets. YoLong fabricates to PED and AS1210 certification and specifications, ensuring that YoLong uni-tank fermenters meet government stipulations and requirements in different countries.

uni-tank

uni-tank 5hl unitank

5hl unitank side manway

side manway spunding valve

spunding valve 5bbl unitanks

5bbl unitanks spray ball

spray ball sample valve

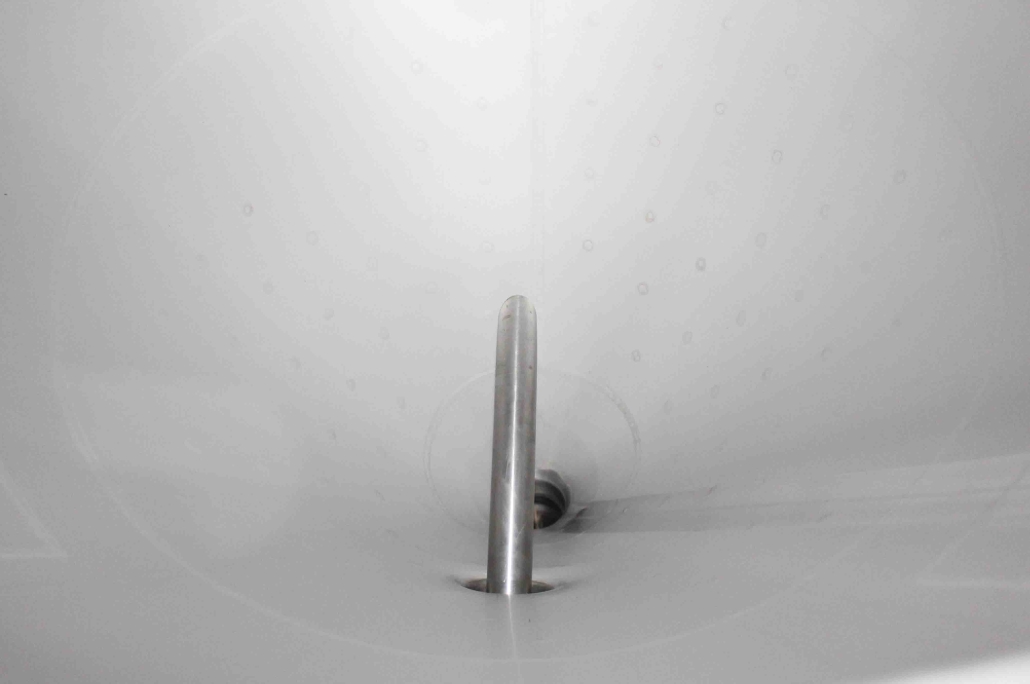

sample valve racking arm

racking arm

Specification

| Specification | Details |

|---|---|

| Capacity | Available from 1/2 bbl to 20 bbl |

| Material | SS 304 construction |

| Top Head | Top dished head with pressure vacuum relief valve |

| Access Points | Top manway or side shadowless manhole |

| Dry Hopping Port | Dry hopping port with cap |

| Cleaning | Sanitary rotary spray ball |

| Insulation | PU foam insulated |

| Carbonation | Carbonating stone for CO2 |

| Cooling | Cooling jacket on cylinder and cone bottom |

| CIP Assembly | Side CIP arm assembly with bung valve and pressure gauge |

| Temperature Monitoring | Sanitary thermowell |

| Sampling | Sample valves |

| Racking Arm | Cone racking arm |

| Bottom Cone | 60 degree to 90 degree cone bottom |

| Discharge | Bottom discharge |

| Legs | Four legs adjustable feet, optional for anti-seismic |

| Internal Finish | Internal shell finish: 2B |

| External Finish | External shell finish: #4 |

| Pressure Certificates | PED for 2014/68/EU, AS1210, etc. |