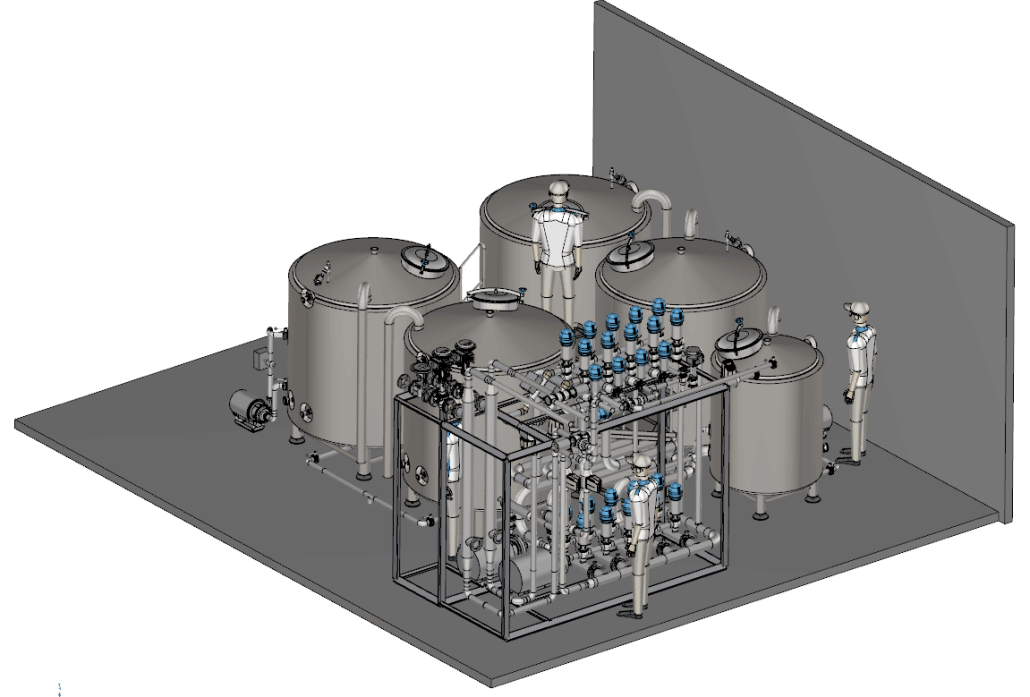

CIP Station

YoLong supplied kinds of food processing equipment and beverage processing equipment, mainly including processing tanks, CIP system, dairy processing equipment and milk processing equipment.

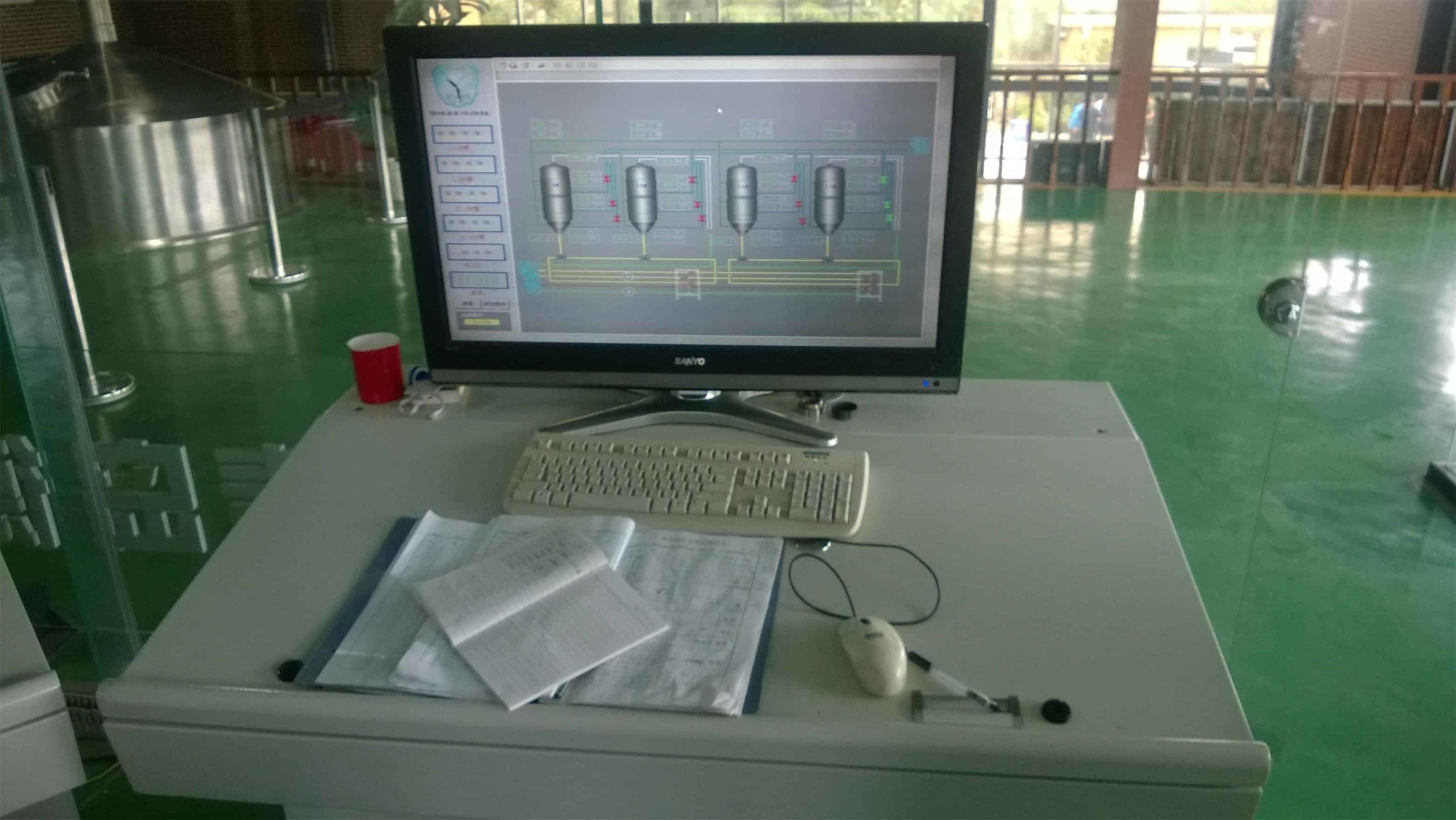

CIP(clean in place) station is a important part in the brewing system, which is mainly used to clean wort and other trubs in the brewing tanks. YoLong will design and custom the CIP system.

The CID system including different vessels to use chemical clean brewery tanks, including acid tank, caustic tank, hot water tank, recovery tanks, ect, which can be combined single vessel to four vessel CIP station.

Specifications